Slurry & Sludge Drying Process

Drum Evaporator/Dryer Technology by ENCON

Step 1:

Place a 55 gallon open top drum onto the drum dolly. Transfer sludge or slurry into the drum. Do not fill beyond 8 inches from top of drum. With the Dryer clamshell walls in the full open position and lid/mixer assembly in raised position, roll the drum into evaporator.

Wrap the rope gasket around the drum so that a positive seal will be made when the clamshell walls are closed.

Step 2:

Close the clamshell walls, ensure seal is made against inside wall of clamshell by rope gasket and secure the walls with latching handles.

Step 3:

Close the pneumatically controlled lid/mixer assembly by moving toggle switch on pneumatic actuator. This will gently force piston down and slowly lower the lid/mixer assembly.

Step 4:

Secure lid/mixer assembly to clamshell walls with latching handles.

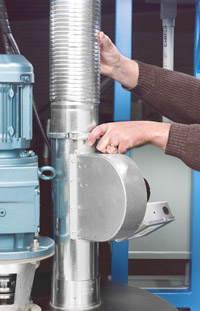

Step 5:

Connect Drum Dryer stack to the flexible section of the permanent exhaust stack with quick connect/disconnect fitting.

Step 6:

Turn the main power selector switch located on control panel to ON position. Turn green selector switch located on dryer panel (Dryer Mode) to ON postion. Set cycle timer on dryer panel to preferred setting. (NOTE: We recommend no more than 8 hours on first cycle)

Your system will begin heating. The lower batch of heating elements will turn on and off according to a factory set control temperature.

Step 7:

A visual inspection of inside of drum should be made periodically through inspection lid to ensure sludge or slurry is not becoming excessively dry.

The heating elements will turn off when the cycle timer counts down to zero indicating completion of the drying cycle. (NOTE: System can be restarted by resetting cycle timer if residue is not adequately dry).

Step 8:

Upon completion of drying cycle, turn Dryer Mode selector switch to off position. Unlatch handles of lid/mixer assembly from clamshell walls. Raise lid/mixer assembly by switching toggle switch on pneumatic actuator. Connect 2 mechanical safety latches (attached to blue frame) to lid/mixer assembly.

Step 9:

Unlatch handles on clamshell wall seam to allow for opening of walls. Roll dolly with dried contents out of Dryer clamshell. Remove dried solids from process drum and into disposal drum.

Return process drum to dolly and fill with sludge or slurry to begin next batch.