Thermal Evaporators

Dramatically Reduce Wastewater Hauling Costs

Evaporation is a time-tested & cost-effective method for reducing the volume of water-based waste

Hauling is Costly

Industrial and commercial facilities that generate wastewater spend too much money paying for hauling & disposal of waste streams that are mostly comprised of water.

Evaporation is Cost Effective

ENCON Thermal Evaporators are utilized by 2,000+ facilities worldwide to evaporate the water portion of water-based wastes, reducing hauling/disposal volumes and cost by up to or even exceeding 99%.

Advantages of ENCON Thermal Evaporators

- Can handle different waste streams simultaneously

- Can handle very challenging and complex waste streams

- Dramatically reduces disposal volume & cost

- Eliminates sewer discharge accountability

- Achieve ZLD

- Safe to operate 24/7 ✔ Low operating costs

- Requires less operator intervention than most wastewater treatment technologies

- Very effective for process stream concentration

Features

Most Capacity Options

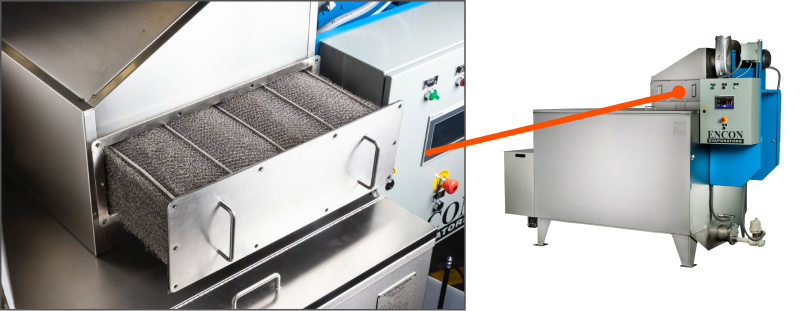

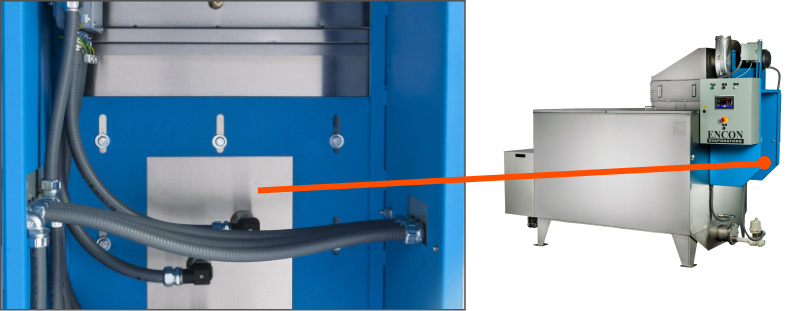

Mist Eliminator System

Superior Fabrication

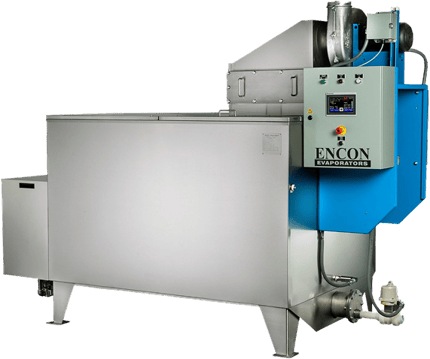

ENCON Thermal Evaporators feature a polished 304 stainless steel exterior for superior corrosion resistance. Fully insulated on all sides (450°F, R-4.3). Standard 316L stainless steel tank and heat exchanger, with higher alloys available for corrosive applications.

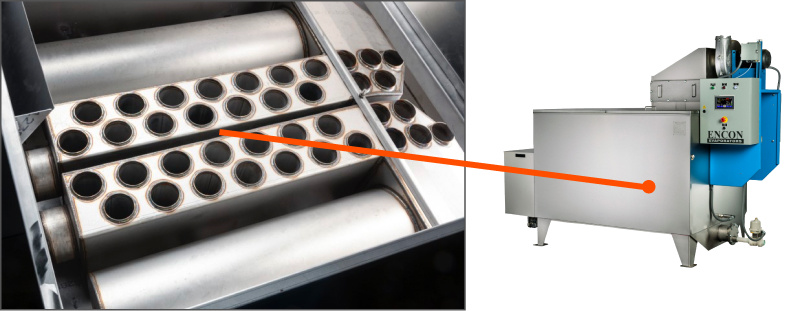

Robust Heat Exchanger

ENCON fuel-heated Thermal Evaporators feature a highly efficient heat exchanger design, reducing fuel costs. Elevated in the tank, it allows solids to settle below for easy cleanout.

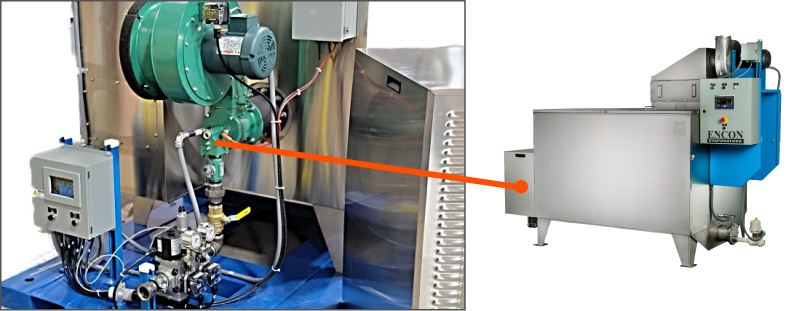

Forced Draft Burner

ENCON fuel-heated Thermal Evaporators use a forced draft burner for efficient, consistent heating with less flame impingement, quieter operation, longer blower life, and minimal impact from atmospheric conditions.

Level Sensing

Durable tuning fork level probes provide reliable level detection to facilitate evaporator auto-fill and fail safe shut down for low and high liquid level conditions.

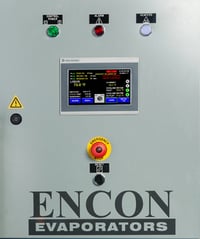

- 7” touch screen HMI panel

- Continuous monitoring of flue gas, chimney, and liquid temperatures

- Continuous level probe diagnostics

- Alarm management and multi-year data logging

- NEMA 4 rated

- Scheduled preventative maintenance alarms

- Control system integration through Modbus TCP/IP

- Remote access through browser or mobile app

- Reliable safety monitoring and shutdown via certified safety relay

The optional ENCON-link service allows you to monitor the evaporator remotely, minimizing operator walk-by’s. Proactive alarm notification allows you to quickly address alarms and minimize downtime. Take advantage of maintenance alerts to help prevent component failures. Monthly performance reports and data driven diagnostics highlight opportunities for process improvement.

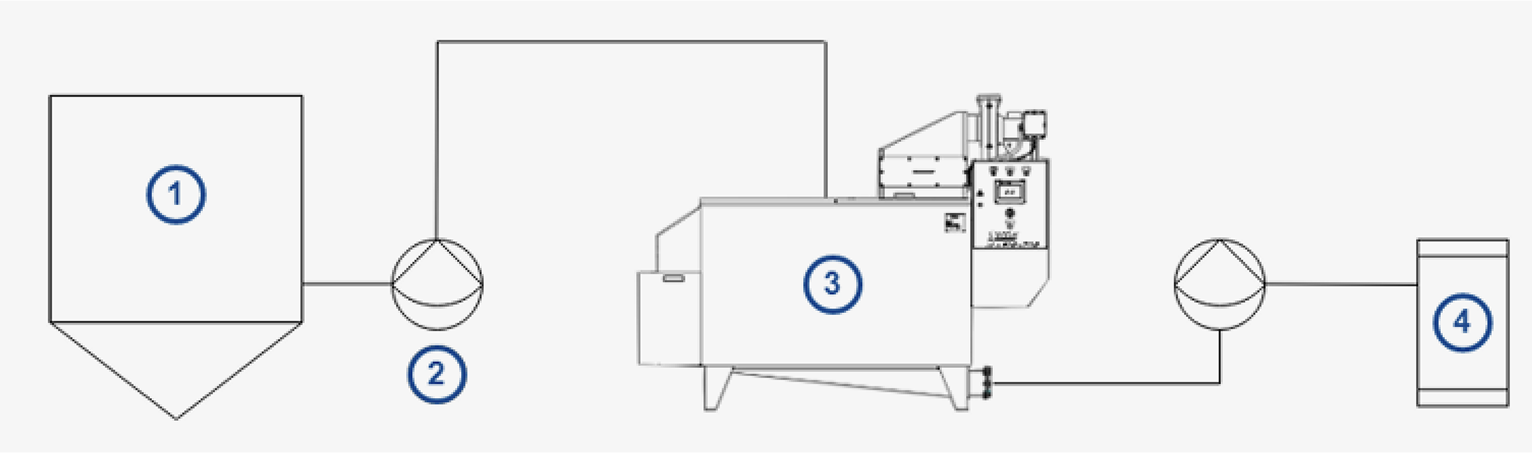

Process Description

Wastewater is automatically pumped or gravity fed into the evaporator through a 1" NPT fitting on the lid.

Once the evaporator is filled to the operating level, the heat source energizes, and water begins to boil.

As water is boiled off, the liquid level in the evaporator tank drops and is automatically replenished with water from the feed tank.

The evaporator continues in this cycle of boiling down a few inches and replenishing with feed water until the end-point concentration is reached.

The end-point concentration is automatically detected via a high fluid temperature or cycle timer setpoint, whichever is reached first.

Upon reaching the end-point concentration, the super-concentrated residue is pumped out of the evaporator to a disposal drum or tank.

Full Range of Upgrades, Accessories and Services to Unlock Your Evaporator’s Full Potential

ENCON offers a full range of upgrades, accessories and services to minimize labor and maximize return on investment.

Recover your wastewater as clean condensate with our condenser package!

Work with our consultative Sales Engineers to spec a turn-key system.

Utilize our air permitting / permit-exemption services.

Automate with auto-dump or auto-oil-decant.

Free Application Feasibility Report

The centerpiece of our consultative approach is our complimentary bench scale analysis of your waste or process stream. This free analysis determines:

- How appropriate the stream is for evaporation

- Estimated reduction percentage

- Recommended materials of construction

- Recommended operating procedures.

Capacities & Dimensions

| Standard Thermal Evaporator Sizes by Evaporation Rate (gal/hr) | 24 Hour Evaporation Capacity - Gallons | Yearly Evaporation Capacity - Gallons (24 hrs/day x 250 days/yr) | Operating Tank Volume - Gallons | System Dimensions - Inches (L x W x H) | System Weight (Empty) |

|---|---|---|---|---|---|

| 10 | 240 | 60,000 | 55 | 68 x 36 x 76 | 650 lbs |

| 18 | 432 | 108,000 | 113 | 80 x 36 x 83 | 800 lbs |

| 28 | 672 | 168,000 | 153 | 100 x 36 x 83 | 1,100 lbs |

| 35 | 840 | 210,000 | 310 | 100 x 53 x 84 | 1,600 lbs |

| 48 | 1,152 | 288,000 | 310 | 100 x 53 x 84 | 1,600 lbs |

| 60 | 1,440 | 360,000 | 425 | 112 x 60 x 86 | 1,800 lbs |

| 72 | 1,728 | 432,000 | 425 | 112 x 60 x 86 | 1,800 lbs |

| 96 | 2,304 | 576,000 | 578 | 194 x 56 x 109 | 4,000 lbs |

| 126 | 3,024 | 756,000 | 752 | 190 x 81 x 111 | 4,900 lbs |

| 165 | 3,960 | 990,000 | 752 | 190 x 81 x 111 | 4,900 lbs |

| 192 | 4,608 | 1,152,000 | 875 | 205 x 86 x 111 | 6,100 lbs |

| 260 | 6,240 | 1,560,000 | 875 | 205 x 86 x 111 | 6,100 lbs |

| 400 | 9,600 | 2,400,000 | 1428 | 236 x 108 x 141 | 11,000 lbs |

| 438 | 10,512 | 2,610,000 | 1565 | 236 x 108 x 153 | 11,700 lbs |

| 650 | 15,600 | 3,900,000 | 3850 | 273 X 128 X 165 | 19,500 lbs |

| Materials of Construction | Exterior Skins: 304 stainless steel, Wetted Parts: 316L Stainless Steel - Standard, High Nickel Alloys, Chloride Resistant Alloys - optional. | ||||

| Heat Source Options | Natural Gas, Propane, Steam, Waste Heat, #2 Fuel Oil, Diesel, Kerosene, Off-spec Landfill Gas, Electric (Available in 8, 15, 24, & 40 gal/hr capacities), Waste Oil (Available in 12, 16, 26, 44, 63 & 88 gal/hr capacities) | ||||

Why Choose ENCON?

Superior Service & Support – We provide industry-leading technical support, ensuring customers receive prompt and knowledgeable assistance.

Consultative Sales Approach – Our expert sales engineers guide you through the process, including a detailed boil analysis of your waste stream to tailor the perfect evaporator solution.

Proven Industry Experience – With over 2,000 installations worldwide, ENCON evaporators are trusted by some of the largest companies, including 3M, GM, Ford, and Caterpillar, for their reliability and performance.

Wide Range of Heat Source Options – The most extensive selection of heat sources in the industry, ensuring the most cost-effective solution for any application.

Largest Thermal Evaporators in the Market – Designed to handle the most demanding industrial needs, with larger capacities than competitors. Proudly designed and manufactured in the USA.

Unmatched Reliability & Performance – ENCON evaporators are built for longevity, offering superior technical advantages and reliability over competitors.

Get a Customized Solution

ENCON Thermal Evaporators offer a wide range of customizable options and accessories to ensure the best fit for your wastewater treatment requirements. With so many configurations available, the best way to determine the right solution is to speak with an expert.

Contact a sales engineer today to discuss your needs and request a quote.