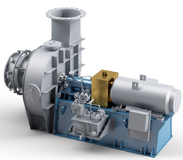

Mechanical Vapor Compression (MVC) Evaporator

The ENCON MVC Evaporator is a forced circulation flash evaporator utilizing mechanical vapor compression. Available in capacities from 300-4,000 gallons/hour, these highly  automated systems operate on steam and compressed air at a typical operating cost of $0.01-$0.02 per gallon of condensate. A variety of material of construction options are available to handle just about any waste stream.

automated systems operate on steam and compressed air at a typical operating cost of $0.01-$0.02 per gallon of condensate. A variety of material of construction options are available to handle just about any waste stream.

Thermal separation processes such as evaporation and distillation can be energy intensive. In conventional evaporators, the energy content of steam vapor produced is lost to a large extent. Using mechanical vapor compression in our MVC Evaporators permits the continuous recycling of this energy by compressing the steam to a higher pressure and temperature. This steam is then used to heat the mother liquid.

Mechanical Vapor Compression not only greatly reduces energy costs, it also reduces the CO2 footprint. Of course, reduced energy costs doesn't matter if you're not getting the results expected. That is why ENCON custom designs and builds each MVC specific to the individual wastewater characteristics to provide the customer with the full purchased evaporation rate. The ENCON MVC Evaporator is designed for heavy duty industrial usage utilizing name brand, high quality components for long lasting performance and safety. Our four step mist-elimination process ensures the highest quality distillate.

Read more on how MVC Evaporator can reduce waste water disposal costs.