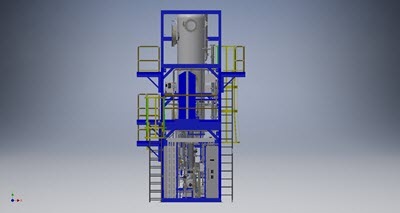

CFE Features & Benefits

ENCON Evaporators custom designs and builds each CFE Evaporator to each customer's individual wastewater characteristics. This allows us to provide the lowest possible operating cost while also providing the full purchased evaporation rate, which is often not possible with "one size fits all" designs.

Each system’s mass and energy balance is created specific to the client application. All evaporator components are selected specifically for client application and client preferences. ENCON will provide full P&ID created to client's specific application and process. Custom design also allows the correct materials of construction to be utilized for corrosion resistance

Controls and HMI

ENCON CFE system comes standard with Allen-Bradley controls. The ENCON system is fully automated from start-up all the way through to automated CIP cycles.

Automation includes: wastewater feed, automatic discharge of concentrated residue from the Separation Tank, automatic transfer of distillate from the distillate sump, and automatic cleaning (Clean-in-Place) of heat exchangers. Numerous variables such as temperature, pressure, and water level are monitored continuously, and will trigger various alarm conditions that notify the operator of deviation from normal operating mode.

Four Step Mist Elimination Process

- Vaned process vessel inlet device to minimize droplet formation and dissipate force into the separation tank.

- Vessel diameter carefully designed for optimal droplet disengagement.

- Chevron vane pack mist eliminator (alloy matches vessel) for removal of larger droplets and decreased loading on mesh mist pad.

- Mesh mist pad (alloy matches vessel) for small droplet removal

Heat Exchangers

Heat exchangers are used on ENCON MVC Evaporators to recycle the energy from the vapor generated from the circulating waste stream. This vapor contains a large amount of energy in the form of latent heat. There are two types of heat exchangers that may be used on an ENCON MVC Evaporator, depending on the application.

Heat exchangers are used on ENCON MVC Evaporators to recycle the energy from the vapor generated from the circulating waste stream. This vapor contains a large amount of energy in the form of latent heat. There are two types of heat exchangers that may be used on an ENCON MVC Evaporator, depending on the application.

Plate and Frame Heat Exchanger:

This type of heat exchanger uses metal plates to transfer heat between two liquids. The major advantages of

this type of heat exchanger are a compact footprint and that the fluids are exposed to a much larger surface area because the fluid spread out over the plates, which facilitates the quick transfer of heat.

this type of heat exchanger are a compact footprint and that the fluids are exposed to a much larger surface area because the fluid spread out over the plates, which facilitates the quick transfer of heat.

Shell and Tube Heat Exchanger:

As the name implies, this type of heat exchanger consists of a shell with a bundle of tubes inside. One fluid runs through the tubes and other fluid flows over the tubes to transfer heat between the fluids. This type of heat exchanger has a larger footprint than a plate & frame heat exchanger, but has the advantage of being much more resistant to scaling and fouling.

MVC Safety

- Pneumatic system depressurizes and is lockable

- Lockable low point drains for complete removal of fluids from process piping

- Components located within easy operator reach to minimize requirement of ladders and fall protection

- Work platforms with OSHA compliant railings and ladders for easy operator access to all components

- LOTO instructions included with equipment manual

- All vessels designed to ASME section VIII pressure vessel code

- Mechanical over pressurization relief devices

- E-stops located at all operator workstations/areas

- Failure position of each device scrutinized to ensure failed position is safe position

High Quality Components

ANSI/API Centrifugal Pumps - feed and recirc.

- Typical is Gould's 3196 XLTi or Sulzer CPT

- Double Mechanical Seals

Seal pot system for mechanical seals

- Open Impellor for handling solids

- Bearing case separated from liquid end of pump

- Motor separated from bearing (long shaft design)

Electric Motor Protection – Blower(s) and Recirc Pump

- Over temperature protection on motor windings

- Aegis grounding rings on bearings

Electrical Panels

- UL/CUL Rated

- SSCR rating of 65,000 amps (typical)

Measurement sensors

Rosemount - magnetic flow meters

Rosemount - magnetic flow meters- Micro Motion - Coriolis mass flow meter

- Badger - Ultrasonic flow meter

- Rosemount RTD temperature sensors and transmitters

- Rosemount Pressure transmitters

- Ashcroft Pressure gauges

- Rosemount Guided Wave Radar Level Probes

- Endress Hauser - Level switches

Process vessels designed to meet ASME Section VIII pressure vessel codes with mechanical safeties (rupture disks)

Valves

2 Piece AVCO valves with re-enforced teflonseats

2 Piece AVCO valves with re-enforced teflonseats- Spring return actuators for fail safe return to safe position

- 2 position limit switches on skid boundary valves

- Analog control valves

- Low point and isolation valves

- Low point drains included in design

- Check valves to prevent back flow

- Festo air solenoid valves with Ethernet/IP control

- 3 way valves on air system to safely depressurize/de-energize system automatically

Piping

Expansion joints used to eliminate pipe stresses on piping and components such as pumps, HX, and vapor compressors. Standard material of construction is EPDM - other materials of construction are available.

- Industrial pipe supports

- Fluid and vapor velocities optimized for client waste water conditions