Thermal Evaporator Features

Blower System

The blower system consists of a 1725 RPM, TEFC, motor with Class-F insulation rated for high temperatures and a heavy gauge cast aluminum blower for durability and longevity. The blower system is extremely quiet and has 3 times the average life expectancy of 3450 RPM motors. Thermal overload protection is included on the blower motor.

Forced Draft Burner

Each fuel heated system consists of a burner with: Honeywell controls; pressure gauge and gas volume meter for monitoring gas inlet conditions; airflow detection and lockout; spark ignition; redundant main valve and burner contactors for maximum safety. FM gas trains and gas flow transmitters are standard on larger systems. The stainless steel burner protection shroud is mounted on a track hanger for ease of removal and reattachment. Fuel sources include Natural gas, Propane, Dual Fuel, Oil, Diesel, and Waste Oil. Low NOx Natural Gas burners are also available.

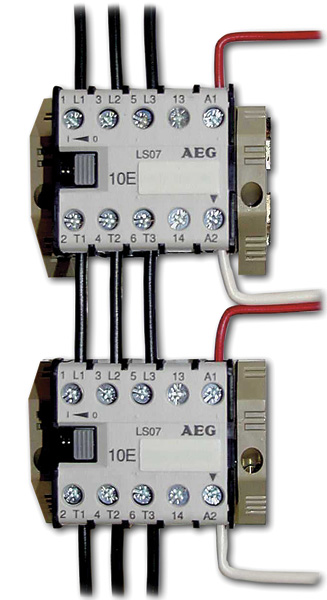

Redundant Burner Contactors

To ensure maximum safety, each burner-fired unit comes with redundant contactors. This critical safety feature ensures the burners will shut down in the event of an alarm condition. If an alarm condition occurs that requires the burners to shut off and the primary duty burner contactor becomes mechanically stuck, the redundant burner contactor will open to ensure system shutdown.

Robust Heat Exchanger

Each ENCON fuel heated Thermal Evaporator utilizes our unique heat exchanger design which provides extremely efficient heat transfer, resulting in reduced fuel costs.

Level Sensing

Our durable tuning fork level probes operate through a piezoelectric crystal that creates a frequency shift as conditions around the probe change. These probes are fabricated of a stainless/titanium alloy for excellent corrosion resistance. Tuning forks offer reliable auto-filling and fail safe shut-down operation. This reliability is complimented by the ongoing diagnostics performed on the level probes by the PLC control system. Optional Hastelloy C probes are available for more corrosive applications.

Mist Eliminator System

Over the years, competing evaporators have been known to discharge unwanted contaminants through their exhaust stack.The ENCON Wastewater Evaporator is designed with a fabricated stainless steel housing and mist eliminator to capture contaminants before they are exhausted. Our effective mist capturing system has the following features for proper functionality:

- Compression fit mist pad to capture unwanted contaminants before exhausting.

- Ease of removal and cleaning to minimize manpower requirement.

- An adequate buffer zone between the water level and the mist pad, to allow fall back of contaminants.

- Adequate mist pad surface area to regulate vapor velocity and prevent blow through of contaminants.

- Monitoring of mist pad loading to ensure consistent evaporation rate.

- Mist pads rated from 2 - 10 microns to capture even the smallest droplets.

V4 Integrated Control & Monitoring System

ENCON Thermal Evaporators come standard with the V4 integrated control and monitoring system, the most advanced system of its type in the industry

Features of this system include:

- The large 7" touchscreen combined with a completely redesigned HMI offers control of every aspect of the evaporation process while at the same time being completely intuitive for daily operation.

- NEMA 4 rated.

- Continuous monitoring of flue gas, chimney and liquid temperatures.

- Continuous level probe diagnostics.

- Datalogging and alarm management as well available remote access through browser or app.

- Control system integration through Modbus TCP/IP

- Built-in ethernet port which allows for easy remote program modifications and/or monitoring and troubleshooting by ENCON personnel.

Cleanout Flange

The ENCON Wastewater Evaporator has a large six inch flanged cleanout cover with a 1 ½" NPT fitting for discharge pump connection and ease of residue removal (8 and 10 gal/hr units have a four inch flanged cleanout cover with a 1" NPT fitting). The tank bottom slopes towards the cleanout, making tank cleaning an efficient task compared to our competitor's 2" or 4" opening.