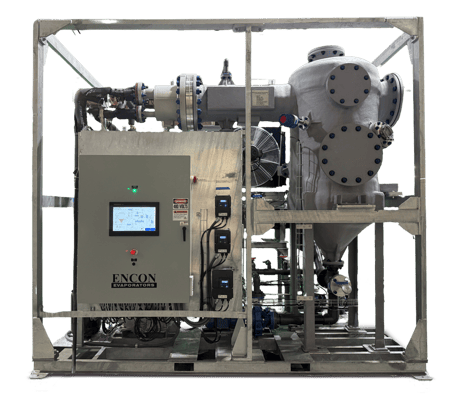

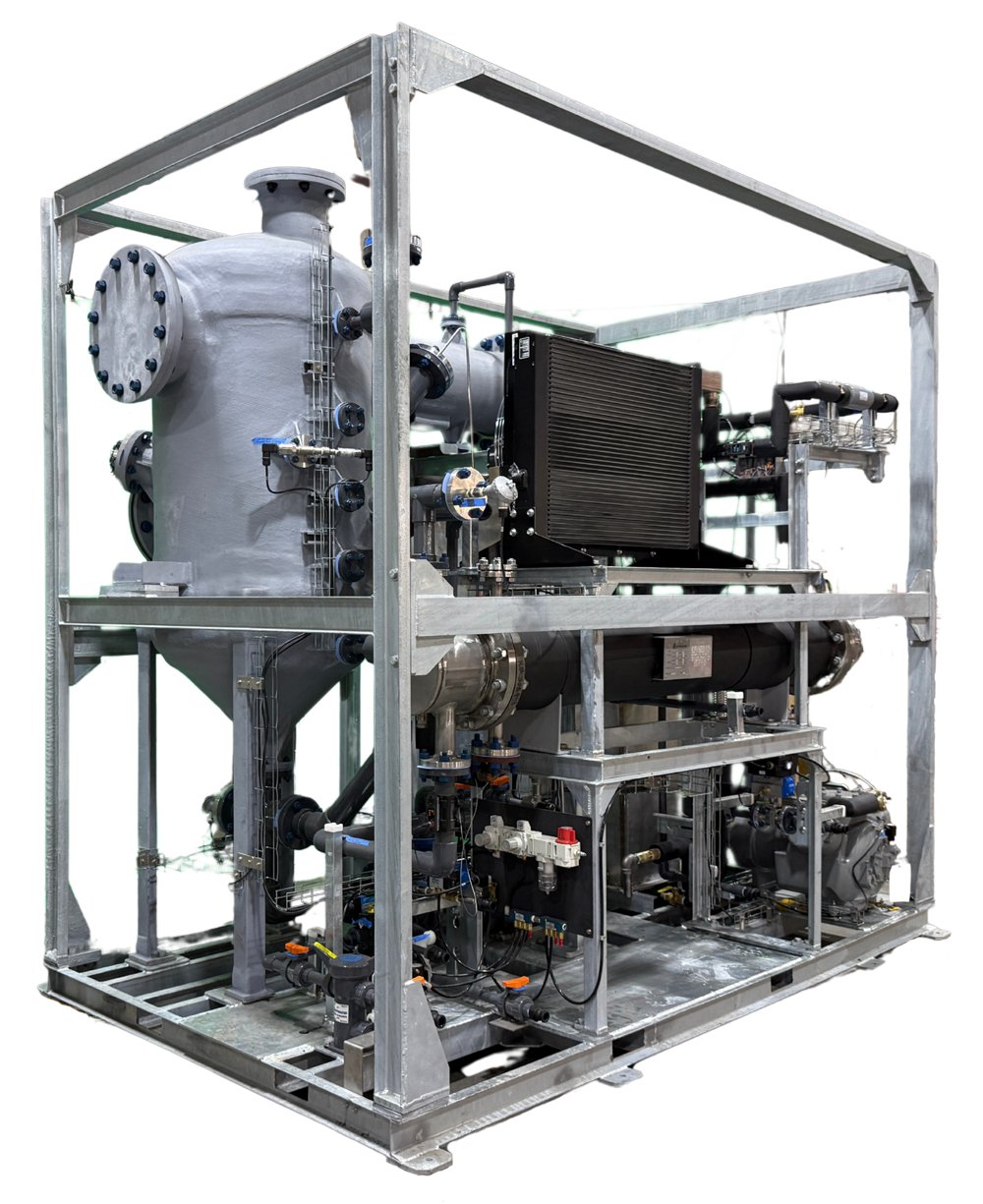

Vacuum Heat Pump (VHP) Evaporator

Produces clean condensate safe for sewer discharge, cutting hauling disposal costs.

The ENCON Vacuum Evaporator is an energy efficient, cost-effective, and environmentally friendly alternative to traditional wastewater treatment or disposal methods. The ENCON Vacuum Evaporator converts contaminated wastewater to clean condensate.

Hauling is Costly

Industrial and commercial facilities that generate wastewater spend too much money paying for hauling & disposal of waste streams that are mostly comprised of water.

Evaporation is Cost Effective

ENCON Evaporators are utilized by 2,000+ facilities worldwide to evaporate the water portion of water-based wastes, reducing hauling/disposal volumes and cost by up to or even exceeding 99%.

Advantages of ENCON VHP Evaporators

- Can handle different waste streams simultaneously

- Can handle very challenging and complex waste streams

- Dramatically reduces disposal volume & cost

- Eliminates sewer discharge accountability

- Achieve ZLD

- Safe to operate 24/7

- Low operating costs

- Requires less operator intervention than most wastewater treatment technologies

- Very effective for process stream concentration

| Evaporator Model | Evaporation Rate (Gallon/Hr) |

|---|---|

| VHP-20 | 20 GPH |

| VHP-40 | 40 GPH |

| VHP-70 | 70 GPH |

Features

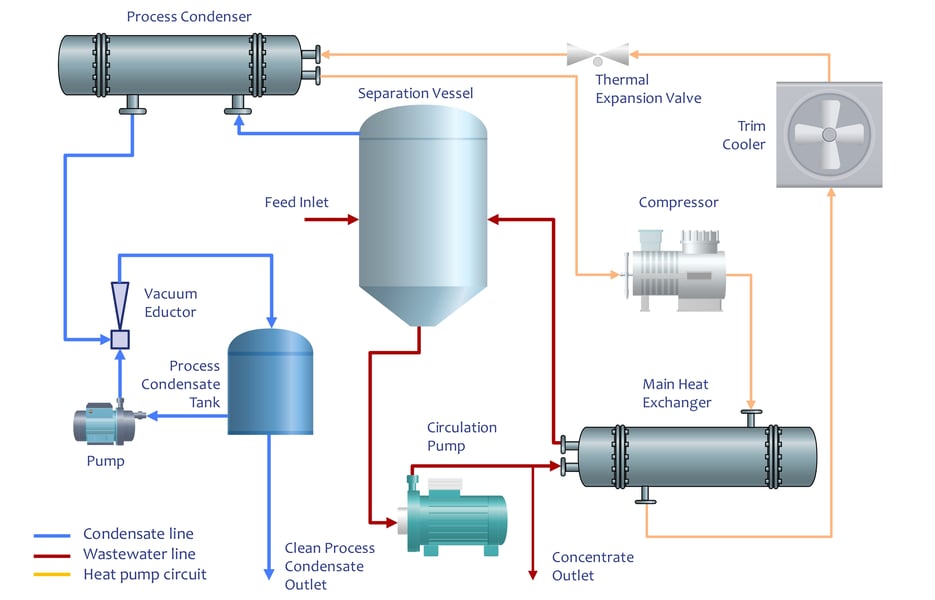

Process Description

KEY DESIGN PRINCIPLES

- Evaporation takes place at low temperature and reduced pressure conditions. The pressure in the separation vessel ranges from 0.7 psia to 1 psia. At this pressure, the boiling point of water is 90-102 °F.

- Energy consumption: 0.57 kWh/gallon of distillate.

- Refrigerant: The ENCON Vacuum Evap uses R513a which has a low Global Warming Potential (GWP) of 573 which is less than half that of competitors systems, is Freon-free, and has an ozone depletion potential of zero.

- Continuous flow system: this means that the solution in the separation vessel is maintained at a constant, maximum desired concentration. Concentrate is continuously discharged and replaced by fresh inlet solution.

Free Application Feasibility Report

The centerpiece of our consultative approach is our complimentary bench scale analysis of your waste or process stream. This free analysis determines:

- How appropriate the stream is for evaporation

- Estimated reduction percentage

- Recommended materials of construction

- Recommended operating procedures.

Full Range of Upgrades, Accessories and Services to Unlock Your Evaporator’s Full Potential

ENCON offers a full range of upgrades, accessories and services to minimize labor and maximize return on investment.

Work with our consultative Sales Engineers to spec a turn-key system

Material of construction upgrades for corrosive waste streams

Automated chemical clean in place (CIP) systems

Service contracts

Why Choose ENCON?

Superior Service & Support – We provide industry-leading technical support, ensuring customers receive prompt and knowledgeable assistance.

Consultative Sales Approach – Our expert sales engineers guide you through the process, including a detailed boil analysis of your waste stream to tailor the perfect evaporator solution.

Proven Industry Experience – With over 2,000 installations worldwide, ENCON evaporators are trusted by some of the largest companies, including 3M, GM, Ford, and Caterpillar, for their reliability and performance.

Wide Range of Heat Source Options – The most extensive selection of heat sources in the industry, ensuring the most cost-effective solution for any application.

Largest Thermal Evaporators in the Market – Designed to handle the most demanding industrial needs, with larger capacities than competitors. Proudly designed and manufactured in the USA.

Unmatched Reliability & Performance – ENCON evaporators are built for longevity, offering superior technical advantages and reliability over competitors.