Evaporation Technology

- Home

- »

- Evaporation Technology

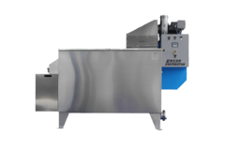

A time-tested method for reducing the water portion of water-based wastes

In its simplest form, the evaporator converts the water portion of water-based wastes to water vapor, while leaving the higher boiling point contaminants behind. This greatly minimizes the amount of waste that needs to be hauled off-site.