Drum Evaporator / Dryer

Reduce waste disposal costs and simplify cleanup with our Drum Evaporator/Dryer that turns liquids into dry, landfill-ready solids.

Evaporation is a time-tested & cost-effective method for reducing the volume of water-based waste

Hauling is Costly

Industrial and commercial facilities that generate wastewater spend too much money paying for hauling & disposal of waste streams that are mostly comprised of water.

Evaporation is Cost Effective

ENCON Evaporators are utilized by 2,000+ facilities worldwide to evaporate the water portion of water-based wastes, reducing hauling/disposal volumes and cost by up to or even exceeding 99%.

Advantages of ENCON Evaporators

- Concentrate, Dry & Dispose of residue in one drum

- Can handle different waste streams simultaneously

- Can handle very challenging and complex waste streams

- Dramatically reduces disposal volume & cost

- Eliminates sewer discharge accountability

- Achieve ZLD

- Low operating costs

- Requires less operator intervention than most wastewater treatment technologies

What is a Drum Dryer?

ENCON Drum Evaporators are designed for dewatering concentrated slurries and sludge to a dry landfillable condition. These systems are electrically heated, operate in batch mode, and are controlled on a time and temperature basis.

Features

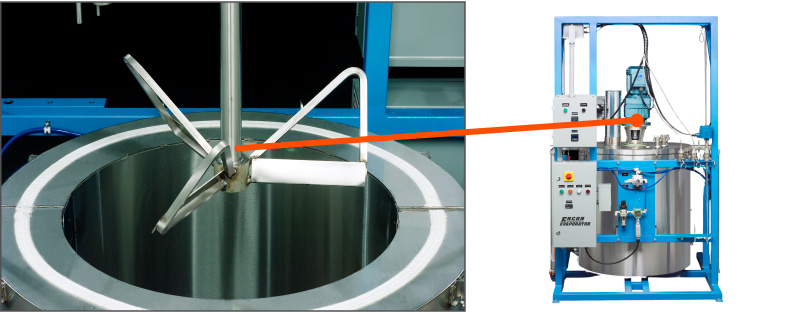

High torque/low speed mixing system

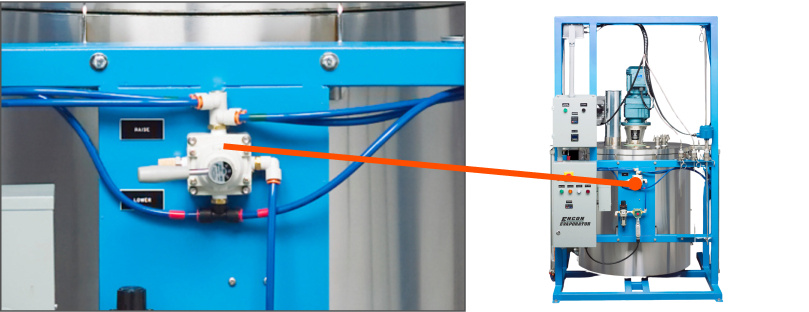

Pneumatic Lifting System

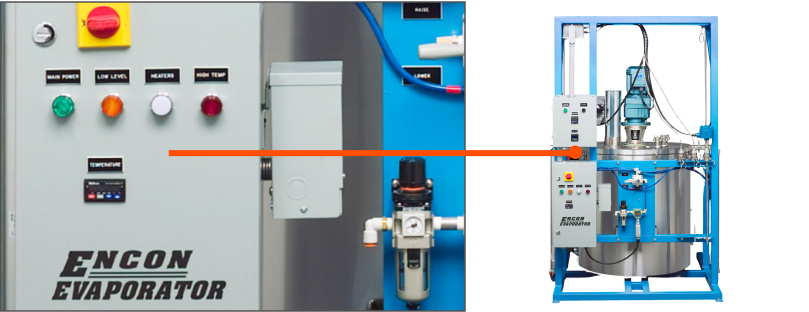

Simple to operate

Concentrate, dry, & dispose of residue in one drum

Process Description

Step 1

Wrap the rope gasket around the drum so that a positive seal will be made when the clamshell walls are closed.

Step 2

Step 3

Step 4

Your system will begin heating. The lower batch of heating elements will turn on and off according to a factory set control temperature.

Step 5

The heating elements will turn off when the cycle timer counts down to zero indicating completion of the drying cycle. (NOTE: System can be restarted by resetting cycle timer if residue is not adequately dry).

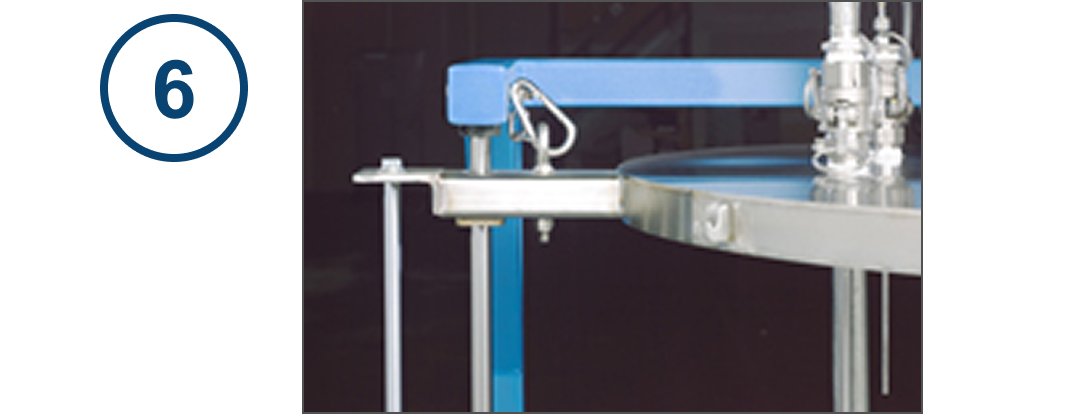

Step 6

Step 7

Return process drum to dolly and fill with sludge or slurry to begin next batch.

Full Range of Upgrades, Accessories and Services to Unlock Your Evaporator’s Full Potential

ENCON offers a full range of upgrades, accessories and services to minimize labor and maximize return on investment.

Recover your wastewater as clean condensate with our condenser package!

Work with our consultative Sales Engineers to spec a turn-key system.

Utilize our air permitting / permit-exemption services.

Contact the ENCON Service team for the full lineup of upgrades and accessories.

Free Application Feasibility Report

The centerpiece of our consultative approach is our complimentary bench scale analysis of your waste or process stream. This free analysis determines:

- How appropriate the stream is for evaporation

- Estimated reduction percentage

- Recommended materials of construction

- Recommended operating procedures.

Capacities & Dimensions

Specifications

- Programmable cycle timer with digital display.

- 316L Mist Eliminator

- 4 inch ceramic fiber insulation in clamshell walls

- 2 inch ceramic fiber insulation in lid.

- Illuminated power on and drum dryer mode selector switches.

- Disconnect switch on control panel door.

- Drum dolly with industrial grade casters.

Dimensions and Specifications

Drum Evaporator/Dryer Dimensions: 66 x 62 x 103 inches in open position (L x W x H)

Drum Dimensions (NOTE: Drum Supplied by Customer): 21 – 23 inches (D) x 36 inches max (H)

Drying Rate: Variable based on application.

Drum Evaporator/Dryer Stack Dimensions: 5 inch diameter x 25 foot max. straight vertical length

Drum Evaporator/Dryer Volumetric Airflow: 120CFM at 70F and 0.2 inches of water column

Why Choose ENCON?

Superior Service & Support – We provide industry-leading technical support, ensuring customers receive prompt and knowledgeable assistance.

Consultative Sales Approach – Our expert sales engineers guide you through the process, including a detailed boil analysis of your waste stream to tailor the perfect evaporator solution.

Proven Industry Experience – With over 2,000 installations worldwide, ENCON evaporators are trusted by some of the largest companies, including 3M, GM, Ford, and Caterpillar, for their reliability and performance.

Wide Range of Heat Source Options – The most extensive selection of heat sources in the industry, ensuring the most cost-effective solution for any application.

Largest Thermal Evaporators in the Market – Designed to handle the most demanding industrial needs, with larger capacities than competitors. Proudly designed and manufactured in the USA.

Unmatched Reliability & Performance – ENCON evaporators are built for longevity, offering superior technical advantages and reliability over competitors.

Get a Customized Solution

ENCON Thermal Evaporators offer a wide range of customizable options and accessories to ensure the best fit for your wastewater treatment requirements. With so many configurations available, the best way to determine the right solution is to speak with an expert.

Contact a sales engineer today to discuss your needs and request a quote.